Medicine generally has operations such as drug decoction, gelatinization, drying, capsule making, and high-temperature disinfection of medical equipment. It is more appropriate to choose a steam boiler. In terms of medical care and hygiene, it is mainly used for the disinfection of medical supplies (patient gowns, bed sheets, etc.), steaming rice in the kitchen, and heating of wards. Both steam and hot water will be needed. The pharmaceutical industry has high requirements for environmental hygiene. When selecting the type of boiler, whether the emission coefficient meets the standard and whether the steam quality is good must be taken into consideration.

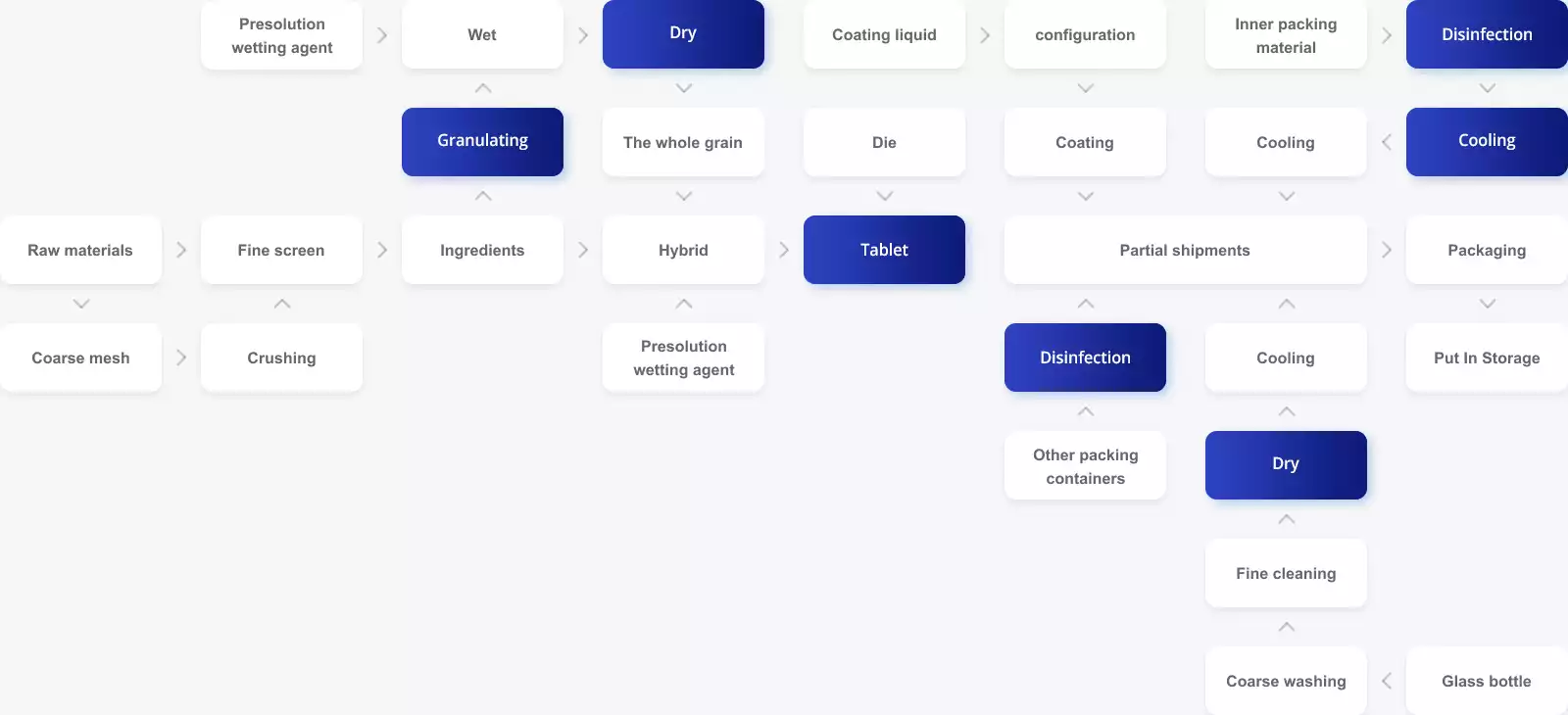

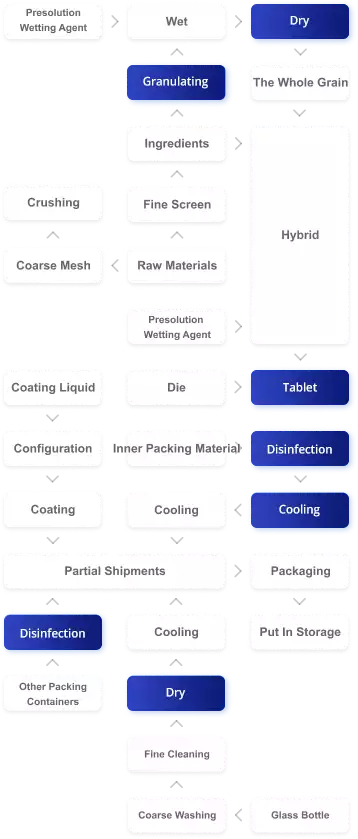

In the process of drug production, raw material processing, disinfection and drying, and pressing into capsules or tablets all require steam boilers to provide high-temperature steam. At the same time, the steam boiler can also be used as power to promote the normal operation of the equipment. However, due to the special nature of the pharmaceutical industry, the pharmaceutical process has very high requirements for steam, and it is necessary to stabilize the output and ensure the quality of the steam.